The importance of health and safety in the workplace

Statistics on accidents at work and occupational illnesses.

Every year, hundreds of thousands of workplace accidents are recorded, along with hundreds of fatalities. In 2021, the latest figures to date, over 600,000 workplace accidents were reported, and 700 fatalities.

Some sectors are more at risk than others, such as construction, agriculture, transport and logistics, mining and woodworking.

Accidents can happen in the workplace, but also on the way to and from work.

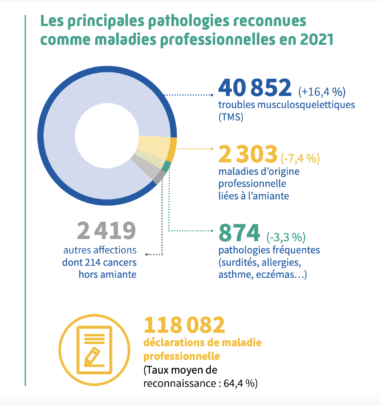

When it comes to work-related illnesses, the vast majority are linked to musculoskeletal disorders (MSDs), as illustrated by this graph published in the November 2022 Health Insurance Annual Report.

Legal and financial implications for companies

Employers’ civil and criminal liability

Employer liability in the context of occupational illness or injury can take two distinct forms: civil liability and criminal liability.

Civil liability is invoked when the employer, by failing to meet his obligations under the French Labor Code, causes or contributes to the occurrence of an occupational disease or accident. This entails an obligation to pay compensation in the form of damages, which are paid by the company or its liability insurance, in addition to the basic compensation.

On the other hand, the employer may be held criminally liable if he breaches a public order obligation of the French Penal Code, likely to cause an occupational disease or accident. In most cases, the company manager is held responsible. This stems from its obligation to guarantee compliance with health and safety regulations. However, he may delegate this responsibility to a specific committee, provided that this committee has the necessary authority to make decisions relating to health and safety, has the appropriate equipment, and benefits from dedicated training.

The consequences of the employer’s criminal liability vary according to the seriousness of the offence, ranging from a 2nd class fine to imprisonment and a fine of up to €75,000. These penalties depend on the nature of the damage suffered, in particular the duration of work incapacity, and the employer’s degree of responsibility.

Significant costs for the employer

The overall cost of work-related accidents and illnesses is significant, often exceeding four to ten times the initial direct cost, or even more. These incidents generate a multitude of indirect costs that are difficult to quantify precisely. In addition to the suffering imposed on the victimized worker and his or her family, which is difficult to compensate for, employers also suffer significant financial losses.

For employers, direct costs include payment for work not done, medical expenses and compensation, the cost of replacing or repairing damaged equipment, the reduction or temporary stoppage of production, increased training and administrative expenses, the possible reduction in the quality of work, as well as a negative impact on the morale of other employees.

Indirect costs include the replacement of an injured or sick employee, the training of a new employee and the time needed to adapt, the time it takes for the new employee to reach the same productivity as the old one, and the time spent on compulsory investigations, report writing and various formalities. Accidents often cause concern among other workers, creating tension in relations between employees and employers. What’s more, poor health and safety conditions can tarnish a company’s image.

All in all, the overall cost of occupational accidents and diseases is high for workers, their families and employers alike. On a national scale, it is estimated that these costs can represent as much as 3-4% of gross GDP, although the total cost remains difficult to determine due to the multitude of indirect costs that are difficult to measure.

The benefits of prevention

Implementing preventive measures in the workplace generates numerous benefits, making a significant contribution to the overall health and prosperity of the company.

Reducing accidents and occupational illnesses.

First and foremost, prevention is reflected in a clear reduction in occupational accidents and illnesses. By instituting safety protocols, providing adequate training and raising employee awareness of potential risks, companies create a safer working environment, thereby limiting incidents harmful to workers’ health.

Savings on direct and indirect costs

This reduction in occupational accidents and illnesses has a direct impact on the company’s financial health, through substantial savings on the direct and indirect costs of occupational accidents and illnesses. By reducing the number of incidents, companies cut expenses related to medical care, compensation, replacement of damaged equipment, and training of new workers.

Indirect costs, such as time spent on investigations and administrative formalities, as well as improved working relations, are also positively affected. According to

PIC magazine

(Prévention Individuelle et Collective), for every 1 euro invested in prevention, the return on investment for the company is 2.70 euros.

Improved productivity and employee engagement

What’s more, prevention in the workplace translates into a significant improvement in employee productivity and commitment. By creating an environment where safety is a priority, employees feel valued and protected, which translates into greater motivation and commitment to their tasks. Workers who feel safe are more likely to actively participate in company initiatives and contribute positively to their working environment. This increase in employee engagement has a direct impact on overall company productivity, as engaged teams are more efficient, creative and resilient in the face of business challenges.

Prevention in the workplace is not simply a regulatory imperative, but a sound investment with multiple positive spin-offs. It offers a triple opportunity: reducing the risk of accidents and occupational illness, making substantial savings on direct and indirect costs, and boosting employee productivity and commitment. By placing prevention at the heart of their strategy, companies promote a healthy, safe working environment conducive to long-term growth.

How to implement effective prevention

Implementing effective prevention within a company is based on a methodical process that includes in-depth risk analysis, staff training and awareness-raising, and a continuous improvement approach.

Risk analysis and assessment

First and foremost, risk analysis and assessment is the cornerstone of any prevention strategy.

setting up a DUERP

(Document Unique d’Evaluation des Risques Professionnels). This involves the careful identification of potential hazards in every aspect of the company’s operations. Safety and personnel managers carry out detailed assessments, examining processes, equipment and the working environment. By understanding the specific risks to which employees are exposed, the company can then develop targeted prevention plans, incorporating appropriate safety measures to minimize these risks. This first step lays the foundations for a proactive, personalized approach to the prevention of occupational accidents and illnesses.

Employee training and awareness

Staff training and awareness-raising are the second cornerstone of successful prevention. Employees must be made aware of the potential risks associated with their specific tasks, and equipped with the skills needed to prevent them. Regular training sessions, covering topics such as safety procedures, proper use of equipment and first aid, are essential. Raising awareness can also be reinforced by internal communication campaigns, posters in the workplace and regular reminders. A well-informed, risk-aware workforce actively contributes to the company’s safety culture.

In addition, well-trained employees are more likely to recognize the first signs or symptoms of an occupational disease, and thus act before a situation worsens.

Continuous improvement

Finally, continuous improvement ensures the long-term sustainability of prevention practices. Companies must set up a system for periodically evaluating their safety initiatives. This includes regularly reviewing existing procedures in the light of new data or operational changes, identifying new opportunities for improvement, and constantly adjusting prevention policies in line with feedback. A commitment to continuous improvement ensures that prevention remains adapted to changes in the working environment and new safety information.

To develop an effective health and safety program, all players must feel involved, whatever their hierarchical level within the company. Employees need to know who is responsible for health and safety issues. The role of the health and safety representative is essential in preventing any problems that may arise.

The DUERP: a key prevention tool

The Document Unique d’Évaluation des Risques Professionnels (DUERP) is an essential tool in workplace safety management. The purpose of this document is to identify, assess and prevent the occupational risks to which employees may be exposed within a company.

The primary function of the DUERP is to provide an exhaustive inventory of all the potential risks present in the workplace. This encompasses risks associated with work activities, the equipment used, the substances handled, and the working environment as a whole. An in-depth analysis is carried out to identify factors that could compromise the health and safety of workers.

The main aim of the DUERP is to assess these risks, by measuring their probability of occurrence and their severity. This assessment makes it possible to rank risks according to their criticality, which helps to establish priorities in terms of intervention and the implementation of preventive measures. This proactive approach aims to anticipate potential incidents and prevent them before they occur, thus contributing to the safety and well-being of our workers.

The DUERP also serves as a basis for defining and implementing preventive actions. By identifying the measures needed to reduce or eliminate the risks identified, the company can draw up a concrete action plan. This may include adjustments to working methods, investment in new safety equipment, specific training for employees, or any other initiative aimed at minimizing identified risks.

In short, the Document Unique d’Évaluation des Risques Professionnels (Single Occupational Risk Assessment Document) is an essential pillar of a company’s prevention approach. It not only provides a complete inventory of risks, but above all enables us to assess their relative importance and guide the implementation of appropriate preventive measures. By placing safety at the heart of the management of professional activities, the DUERP contributes to the creation of a safe and healthy working environment for all employees.

Do you need help drawing up or updating your DUERP? Our occupational health and safety experts are here to help:

discover our DUERP offer

.

Feedback and case studies

At Boost’RH, our

expert health and safety consultants

intervene within companies of all sizes and in all sectors, in prevention or following an accident.

In response to an accident, our consultants will set up a cause tree to understand how the accident occurred. Following this, an action plan will be proposed to ensure that such an accident cannot happen again, and managerial safety visits will be set up to give a voice back to employees in the field.

In prevention, the aim is to monitor two key indicators in order to reduce them:

- Frequency rate: proportion of work-related accidents;

- Severity rate: proportional to the duration of absence from work.

The method used is the VMS, or Visite Managériale de Sécurité. This methodology aims to give a voice back to the workers in the field.

For example, we intervened in a production workshop where workers were on their feet for 8 hours at a time, with deadlines to meet. A management visit was organized, during which the workers were able to present their problems: swollen legs, swollen ankles due to standing, leading to RSI and fatigue.

A meeting was therefore scheduled with the production and workshop managers and these workers. The methodology aims to re-establish a dialogue between management and workers, and thus involve workers in the search for solutions. During the visit, the workers asked about the possibility of installing anti-fatigue mats. In the VMS method, we act directly if the cost is reduced, so that we can quickly observe the results. If the test is successful, the solution can be rolled out to all the company’s production lines and sites.

In this case, the installation of anti-fatigue mats has not only improved the health and safety of the workers. Productivity actually improved, as they were less tired and could work faster! It’s a virtuous circle.

Generally speaking, the measures taken are extremely pragmatic. By going out into the field, in contact with workers, managers become aware of the conditions, and the approach enables them to renew dialogue with employees who want to feel listened to and considered. This approach is all the more sustainable because, when employees themselves propose solutions, they are more inclined to apply them over time.

Conclusion

In conclusion, the importance of prevention in occupational health and safety is indisputable. Faced with the diversity of risks present in the workplace, it’s crucial to implement preventive measures. From obvious accidents to more subtle hazards such as psychological or ergonomic factors, prevention aims to anticipate and avoid problems rather than solve them after the fact.

It is imperative that elected representatives, unions and employees play an active role in encouraging employers to eliminate hazards at source, rather than forcing workers to adapt to dangerous conditions.

The commitment of management and the active participation of workers are fundamental pillars of any effective occupational health and safety initiative. The real prevention of accidents and illnesses begins with the design of work methods. Promoting a culture of prevention, integrated into all aspects of the working environment, is essential to guarantee the safety and well-being of workers. By investing in prevention, companies not only safeguard the health of their employees, but also boost their productivity and reputation, helping to create sustainable and ethical workplaces.